The real question is not whether the tool looks professional. It is whether the business can show an auditor a working food safety system, end to end, using that tool.

Are online HACCP plan tools accepted by auditors?

Auditors do not “approve” software. They assess whether the HACCP plan and supporting programs meet the chosen standard and match what happens on site.

If the tool helps them build a compliant plan, control changes, train staff, and keep usable records, it can support a successful audit. If it cannot, the tool becomes a risk because gaps show up quickly during document review and site inspection.

What makes a HACCP plan “audit-ready” in practice?

An audit-ready online haccp plan is specific, up to date, and verifiable within minutes through a centralized digital platform. It clearly links identified hazards to their corresponding controls, monitoring procedures, corrective actions, and supporting records, ensuring full visibility and traceability.

Most auditors expect an online haccp plan to demonstrate defined product scope and intended use, a validated flow diagram, a comprehensive hazard analysis with justified decisions, clearly identified CCPs with critical limits, structured monitoring procedures, documented corrective actions, verification activities, and robust document control. In addition, strong prerequisite programs (PRPs) must be fully integrated—rather than treated as standalone HACCP documentation—to ensure end-to-end compliance integrity.

Do these tools create site-specific hazard analyses or generic templates?

Many tools start with libraries, which is helpful, but audit-readiness depends on whether they force site-specific thinking. A hazard analysis must reflect the actual ingredients, processes, equipment, staffing, and customer requirements.

If the tool lets them copy hazards and CCPs without justification, it can produce a plan that looks right but fails basic auditor questions like, “Why is this a CCP here?” or “Where is the evidence this critical limit is appropriate for this product?”

Can an online tool handle prerequisite programs well enough?

HACCP plans rarely pass audits on HACCP content alone. PRPs often decide the outcome because they control most hazards before CCPs are even considered.

They should check whether the tool supports, at minimum, allergen control, sanitation, pest control, supplier approval, traceability and recall, maintenance, calibration, glass and brittle plastic, training, and personal hygiene. If PRPs live in scattered files outside the tool, version control and retrieval can become a problem under audit pressure.

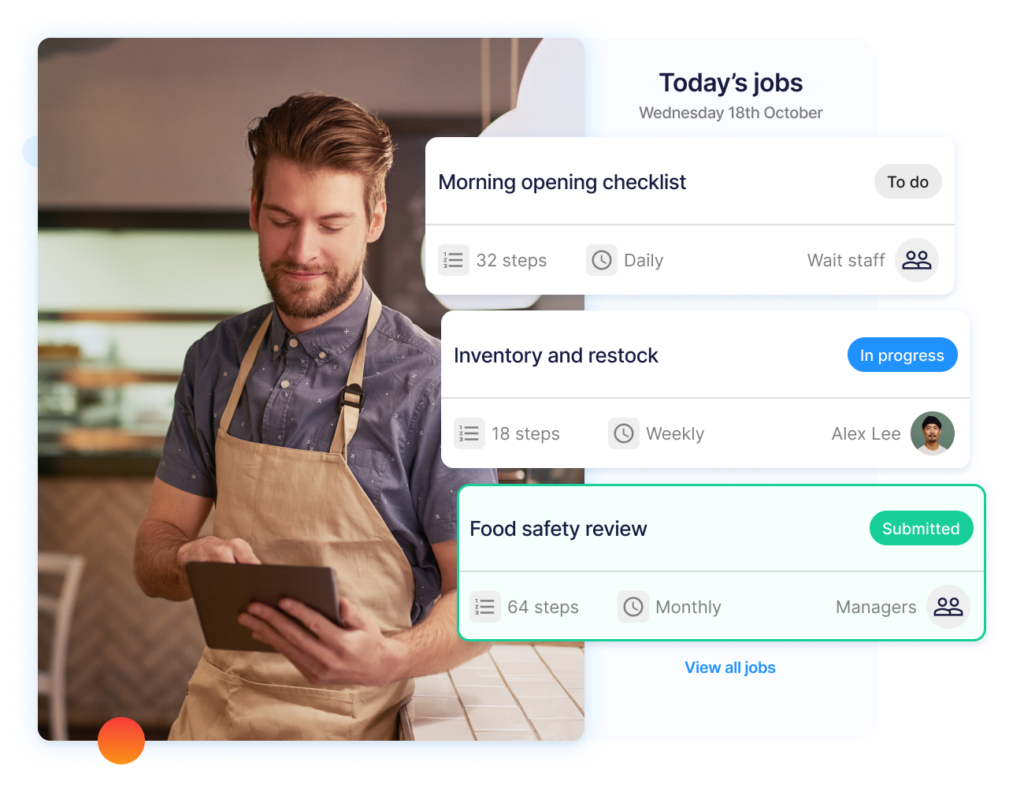

Will the tool produce the records auditors actually want to see?

Auditors follow evidence trails. They will ask for recent monitoring records, deviations, corrective actions, verification logs, calibration certificates, and training records that match the plan.

The tool should make it easy to pull a clear record set for a date range, a line, a product, or a CCP. If it only stores PDFs without structure, or if records can be edited without traceability, auditors may question integrity.

Does it support verification, validation, and reassessment properly?

Audit-ready systems show that controls are checked and still suitable. That means verification is scheduled and completed, and validation is backed by credible evidence.

They should look for features like verification task scheduling, sign-offs, and links to supporting evidence such as scientific references, process authority letters, internal study results, or supplier guarantees. They also need a clear reassessment process after changes, complaints, nonconformities, or new products.

How important are version control, approvals, and audit trails?

They are essential. Auditors want confidence that documents are controlled and changes are authorized.

They should confirm the tool includes revision histories, approval workflows, effective dates, and access controls. A strong audit trail should show who changed what and when, and it should prevent silent edits to historic records. If anyone can overwrite entries, audit-readiness is weakened even if the plan content is technically correct.

Can these tools fit different audit schemes like BRCGS, SQF, ISO 22000, or FDA?

They can, but only if they map to the chosen requirements and terminology. A HACCP plan built for one framework may not satisfy another without adjustments.

They should confirm whether the tool supports HACCP or HARPC terminology where needed, includes scheme-specific document expectations, and allows them to add site procedures and forms beyond the HACCP module. If the tool claims “BRC ready” or “SQF ready,” they should still verify what that truly includes.

What are the most common reasons online HACCP tools fail during audits?

They usually fail for practical, not technical, reasons. The plan exists, but implementation evidence is weak or inconsistent.

Common issues include: CCPs selected without solid reasoning, critical limits not justified, missing PRPs, monitoring records incomplete or backfilled, corrective actions not documented to completion, verification not performed on schedule, calibration gaps, and staff not knowing the plan. Tools cannot fix food safety culture, but they can either support it or expose it.

What should they check before trusting a tool for audit readiness?

They should run a simple test: can they simulate an auditor’s document request and satisfy it quickly. If it takes an hour to assemble records, it is not truly audit-ready.

A practical checklist includes: site-specific hazard analysis controls, PRP coverage, controlled documents, locked records with audit trails, easy reporting, offline or contingency access, user permissions, training logs, verification scheduling, and export options. They should also confirm support responsiveness and whether data can be retrieved if they leave the platform.

So, are online HACCP plan tools audit-ready?

They are audit-ready when they function as a controlled, evidence-driven system, not a template generator. If they help the business build a realistic plan and prove daily execution with credible records, auditors typically accept the output.

The safest approach is to treat the tool as infrastructure. The audit result still depends on whether the site’s hazards are understood, controls are justified, and records reflect what actually happened on the floor.

FAQs (Frequently Asked Questions)

Are online HACCP plan tools accepted by auditors?

Auditors do not approve software itself; they assess whether the HACCP plan and supporting programs meet the chosen standard and reflect actual site practices. If an online tool helps build a compliant plan, control changes, train staff, and maintain usable records, it can support a successful audit. Otherwise, gaps may appear during document review and site inspection.

What makes a HACCP plan ‘audit-ready’ in practice?

An audit-ready HACCP plan is specific, current, and verifiable quickly. It must clearly link hazards to controls, monitoring, corrective actions, and records. Auditors expect defined product use, validated flow diagrams, justified hazard analysis decisions, CCPs with critical limits, monitoring procedures, corrective actions, verification activities, document control, and strong prerequisite programs (PRPs).

Do online HACCP tools create site-specific hazard analyses or just generic templates?

While many tools start with hazard libraries for convenience, true audit-readiness depends on enforcing site-specific hazard analysis reflecting actual ingredients, processes, equipment, staffing, and customer needs. Tools allowing copy-paste of hazards or CCPs without justification risk producing plans that fail auditor scrutiny regarding CCP selection and critical limit appropriateness.

Can online HACCP tools effectively handle prerequisite programs (PRPs)?

HACCP plans rarely pass audits based solely on HACCP content; PRPs often determine outcomes as they manage most hazards before CCPs. Effective tools support allergen control, sanitation, pest control, supplier approval, traceability/recall, maintenance/calibration, glass/brittle plastic control, training, and personal hygiene. PRPs scattered outside the tool can cause version control issues under audit pressure.

Will online HACCP tools produce the records auditors want to see?

Auditors require clear evidence trails including recent monitoring records, deviations logs, corrective actions documentation, verification logs, calibration certificates, and matching training records. Tools should enable easy retrieval of structured records by date range, production line, product or CCP. Storing only PDFs without structure or allowing untraceable edits undermines record integrity in audits.

How important are version control and audit trails in online HACCP systems?

Version control, approvals workflows, effective dates and access controls are essential for audit confidence. Strong audit trails show who made changes and when while preventing silent edits to historic records. Without these controls—even if plan content is correct—the system’s audit-readiness is compromised because unauthorized changes can go unnoticed.

Click here for about: HACCP Hygiene Controls: How Digital Monitoring Improves Standards