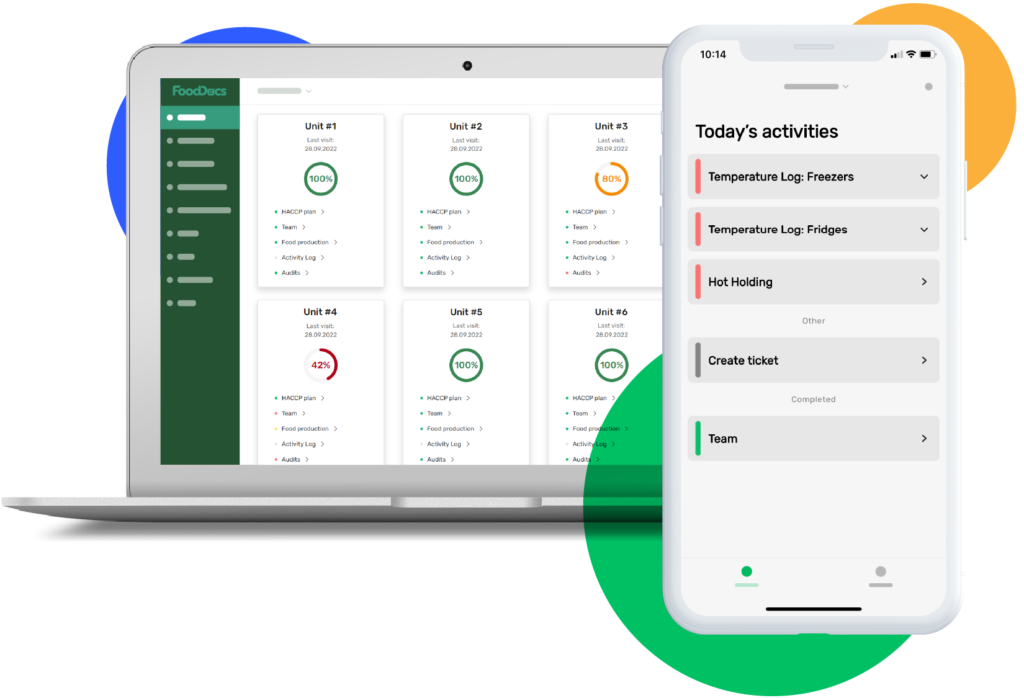

Instead of relying on paper logs and memory, teams use connected tools that timestamp activity, prompt corrective action, and keep a clear record of what happened, when, and by whom.

What do HACCP hygiene controls actually cover?

They cover the practical steps that prevent contamination and keep food safe, especially where hazards are most likely. In most operations, that means controls around people, premises, equipment, cleaning, and temperature management.

These controls typically include personal hygiene rules, handwashing, protective clothing, cleaning and disinfection schedules, allergen controls, pest prevention, waste handling, and verification that procedures are working as intended.

Why do paper checklists and manual logs fall short?

They fall short because they depend on perfect habits in busy environments. When teams are rushed, paper records get completed late, filled in from memory, or skipped entirely.

Paper-based systems create operational blind spots that undermine haccp hygiene oversight. They make it significantly harder to identify trends, validate accountability, or retrieve supporting evidence in a timely manner.

How does digital monitoring raise day-to-day hygiene standards?

It raises standards by building hygiene tasks into daily workflow and making expectations clearer. Digital systems prompt staff to complete checks at the right time and reduce ambiguity about what “good” looks like.

They also create a tighter feedback loop. If a check fails, the system can trigger corrective action steps immediately, notify a supervisor, and prevent the same gap from repeating unnoticed across shifts.

Which hygiene checks benefit most from going digital?

Checks with high frequency and high impact benefit first. These are the tasks that are easy to forget, easy to falsify unintentionally, and most likely to cause a critical failure if missed.

Common examples include cleaning sign-offs, opening and closing hygiene inspections, handwashing compliance checks, probe calibration records, chemical dilution verification, and allergen changeover controls.

How do digital tools improve cleaning and sanitation verification?

They improve verification by linking cleaning tasks to specific areas, equipment, and standards, then recording completion with timestamps and, where needed, photo evidence. That makes it easier to show that cleaning was done properly, not just recorded.

They also support verification activity, such as ATP swab results or visual checks, by attaching results to the relevant task. If standards slip, supervisors can see where, when, and how often it happens.

How does real-time alerting prevent small issues becoming critical?

It prevents escalation by reducing the time between a failure and a fix. If a hygiene check is missed or a result is out of tolerance, alerts can be sent instantly to the right person.

That matters because many hygiene risks worsen with delay. A missed cleaning step, an allergen changeover shortcut, or poor handwashing compliance can compound across service periods before anyone notices without timely signals.

How does digital monitoring strengthen traceability and audit readiness?

It strengthens audit readiness by making records complete, searchable, and consistent. Auditors typically want evidence that controls exist, are followed, and are reviewed, and digital logs make that easier to demonstrate quickly.

Instead of pulling folders and chasing signatures, teams can filter by site, date, CCP, area, or task type. That reduces disruption during audits and helps them respond confidently to questions about gaps and corrective actions.

What role does digital monitoring play in corrective actions and CAPA?

It helps by standardising how issues are recorded, escalated, and closed out. When a check fails, systems can require staff to log the cause, select a corrective action, and confirm completion before the task is marked resolved.

Over time, this builds a useful CAPA trail. Managers can see recurring failures, identify training needs, and adjust procedures based on evidence, rather than relying on anecdotal reports from the floor.

How can digital monitoring improve staff accountability without hurting culture?

It can improve accountability by making responsibilities clear and fair. When tasks are assigned, timed, and recorded consistently, performance discussions rely less on blame and more on facts.

Culture improves when the system supports staff rather than policing them. The best setups use reminders, clear instructions, and quick reporting so teams spend less time on paperwork and more time on doing the right thing.

What should they look for when choosing a digital hygiene monitoring system?

They should look for simplicity first, because adoption determines value. If the tool is slow or complicated, teams will work around it.

Key features to prioritise include offline capability, role-based access, automated reminders, easy corrective action workflows, strong reporting, and exportable audit trails. Integration with temperature monitoring, training records, or maintenance logs can also reduce duplication.

How should they implement digital monitoring without disrupting operations?

They should start small and prove value in one area before scaling. A pilot focused on a high-risk process, such as cleaning verification or allergen controls, usually delivers quick learning.

They should also set clear definitions for pass/fail, train supervisors on review habits, and schedule short feedback sessions during rollout. When teams see fewer last-minute scrambles and easier audits, adoption typically follows naturally.

What is the bottom line on digital monitoring for HACCP hygiene controls?

Digital monitoring improves HACCP hygiene standards by reducing missed checks, speeding up corrective action, and creating stronger evidence for verification and audits.

When implemented with practical workflows and clear expectations, it helps teams stay consistent under pressure and makes hygiene control a daily habit rather than an occasional paperwork exercise.

FAQs (Frequently Asked Questions)

What do HACCP hygiene controls typically cover in food safety management?

HACCP hygiene controls focus on practical steps to prevent contamination and ensure food safety, especially around people, premises, equipment, cleaning, and temperature management. These include personal hygiene rules, handwashing, protective clothing, cleaning and disinfection schedules, allergen controls, pest prevention, waste handling, and verification that procedures are effective.

Why are paper checklists and manual logs insufficient for HACCP hygiene monitoring?

Paper-based records often fall short because they rely on perfect habits in busy environments. They can be completed late, filled in from memory, or skipped entirely. Additionally, paper makes it harder to spot patterns, prove accountability, or retrieve evidence quickly during audits or incidents due to missing sheets or illegible entries.

How does digital monitoring enhance day-to-day HACCP hygiene standards?

Digital monitoring integrates hygiene tasks into daily workflows by prompting staff to complete checks at the right time and clarifying expectations of quality. It enables immediate corrective actions if a check fails by notifying supervisors and preventing unnoticed gaps across shifts, thereby raising overall hygiene standards consistently.

Which specific hygiene checks benefit most from digital monitoring systems?

High-frequency and high-impact tasks benefit most from digital monitoring. These include cleaning sign-offs, opening and closing hygiene inspections, handwashing compliance checks, probe calibration records, chemical dilution verification, and allergen changeover controls—tasks prone to being forgotten or falsified unintentionally.

How do digital tools improve verification of cleaning and sanitation processes?

Digital tools link cleaning tasks to specific areas and equipment with timestamps and photo evidence to confirm proper completion. They also attach verification results like ATP swab tests or visual checks to relevant tasks. This transparency helps supervisors identify when and where standards slip for timely intervention.

In what ways does real-time alerting through digital systems prevent minor issues from escalating into critical problems?

Real-time alerts reduce the delay between detecting a failure and initiating corrective action by instantly notifying the responsible person if a hygiene check is missed or out of tolerance. This rapid response prevents risks like missed cleaning steps or poor handwashing compliance from compounding over time before being noticed.

Click here for about: Online HACCP Plan Tools: Are They Audit-Ready?